When planning drainage technology, it is important to check which material is most suitable for the type(s) of wastewater and the project-specific conditions at the installation location. The substances and concentrations thereof contained in the wastewater, the spatial conditions, the floor constructions and the corresponding types of waterproofing layers must be taken into consideration.

Selection of materials with the KESSEL resistance list

You can use our resistance list to check which material will best withstand the wastewater arising in your application. There you will find a list of the most common types of wastewater with assessments of the different materials with respect to their resistance.

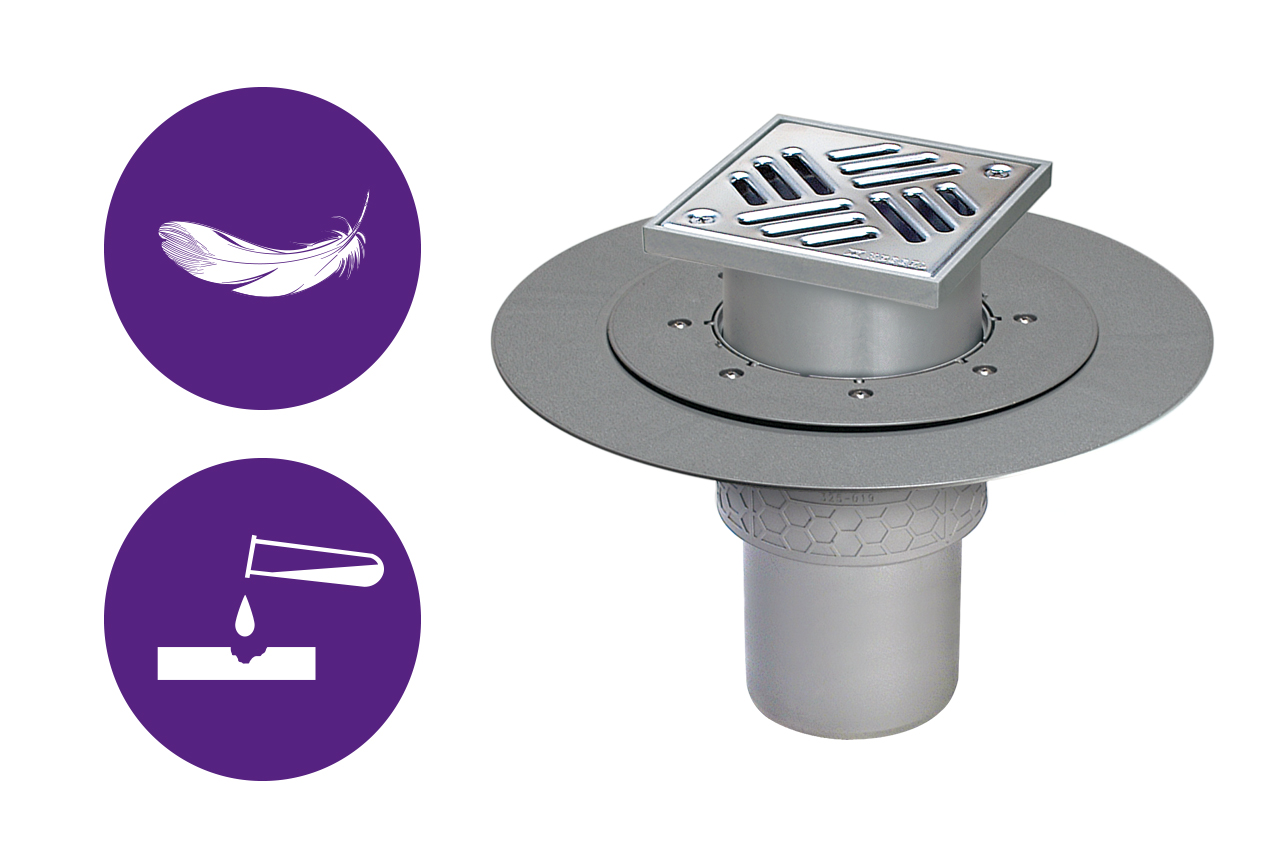

Stainless steel (e.g. V2A, V4A)

Extremely hygienic and therefore a good choice for intensively used places contaminated with bacteria and/or germs, such as breweries, commercial kitchens, hospitals or swimming pools. Requires earthing and corrosion protection.

Grey iron

Suitable for extremely hot environments such as bitumen-coated roofs due to its heat/fire resistance. Corrosion protection and, if necessary, earthing requirements as well as restricted hygiene.

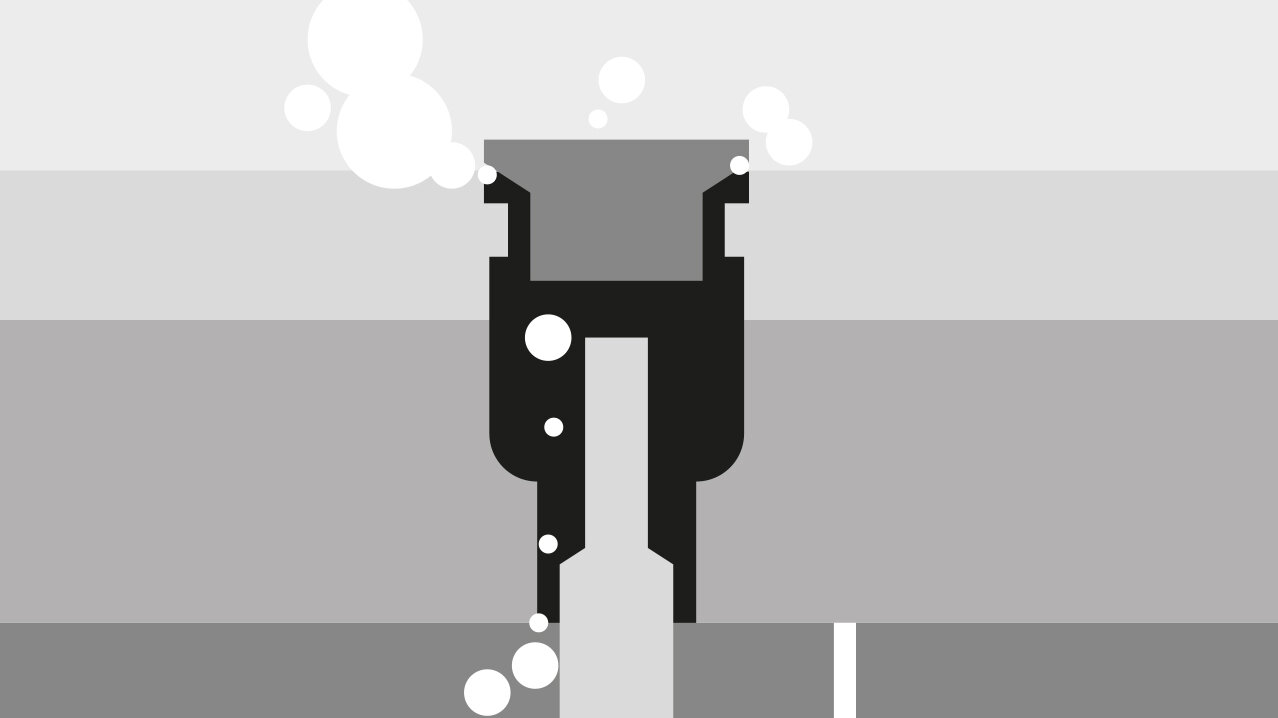

3. Fire protection for drain technology

Proper floor drain protection

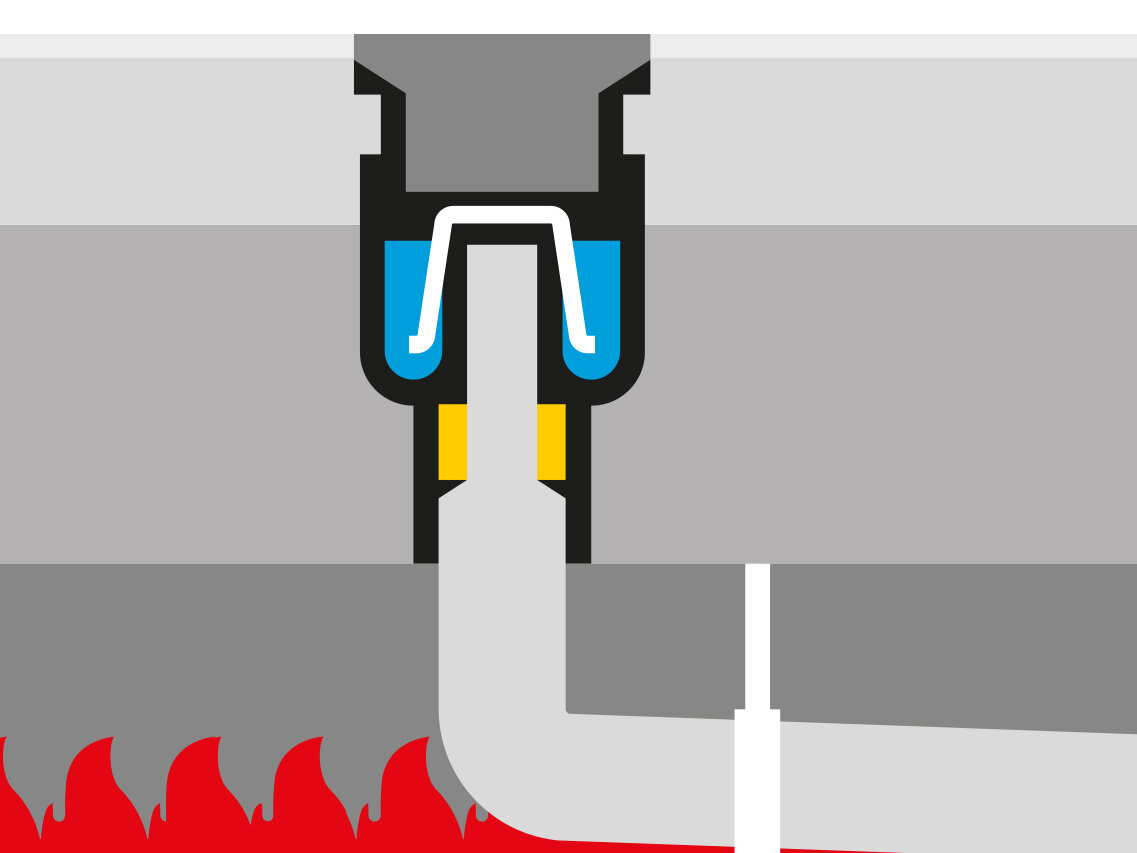

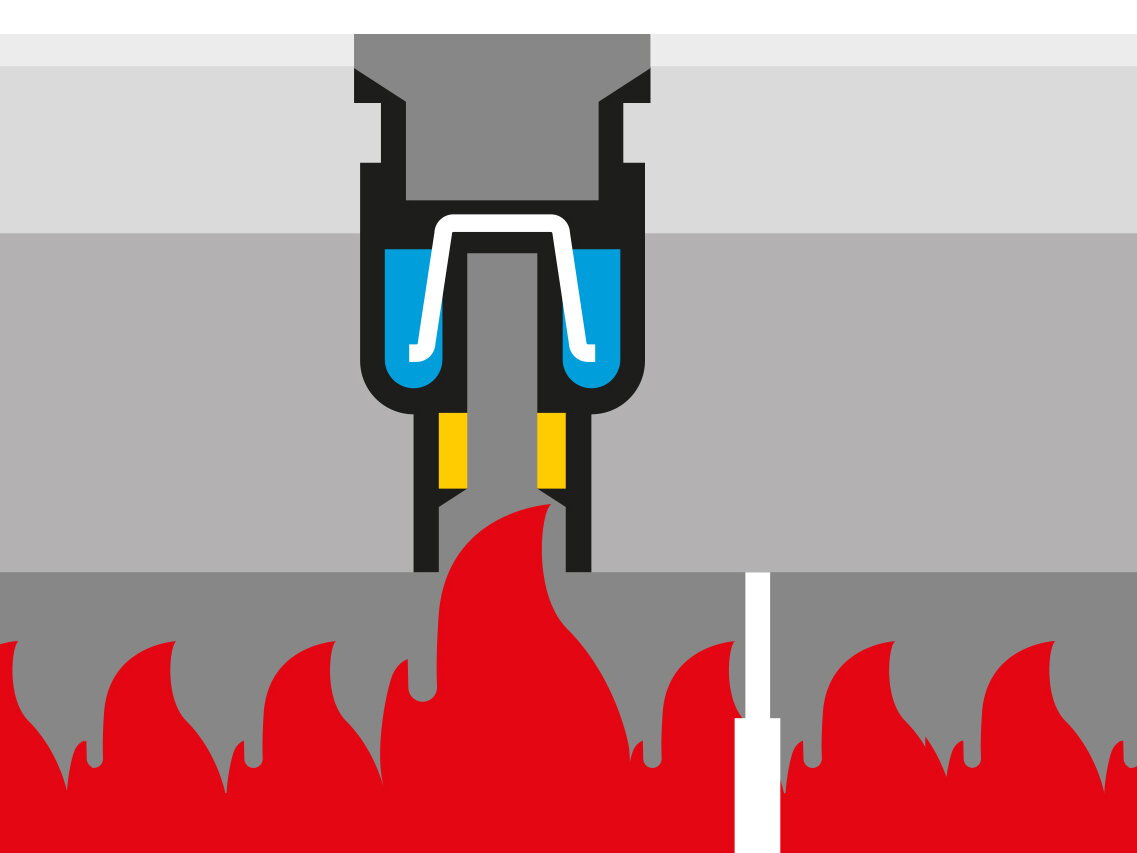

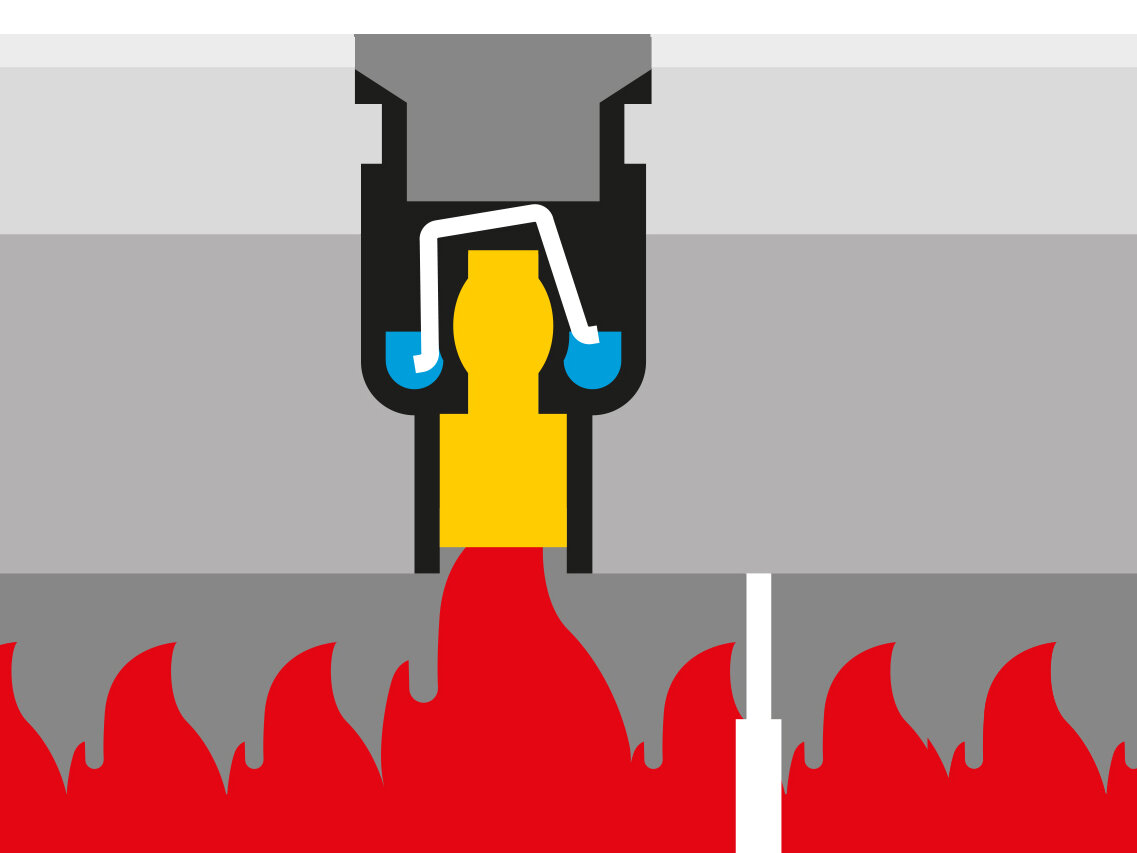

If buildings catch fire, floor drains are potential weak spots through which fire, smoke and toxic gases can spread from room to room. For this reason, the state building regulations stipulate suitable preventive fire protection measures in the area of drainage technology.

Fire resistance classes of floor drains

Different fire resistance classes are prescribed for floor drains depending on the state, region, type of building and installation location. The number value of the fire resistance class specifies the minimum time for which a tested component must be able to withstand a fire in minutes. The fire resistance classes relevant for floor drains are:

- F30 (“fire retardant”)

- F60 (“highly fire retardant”)

- F90 (“fire resistant”)

- F120 (“highly fire resistant”)

Always heed the specifications in your project-specific fire protection concept.

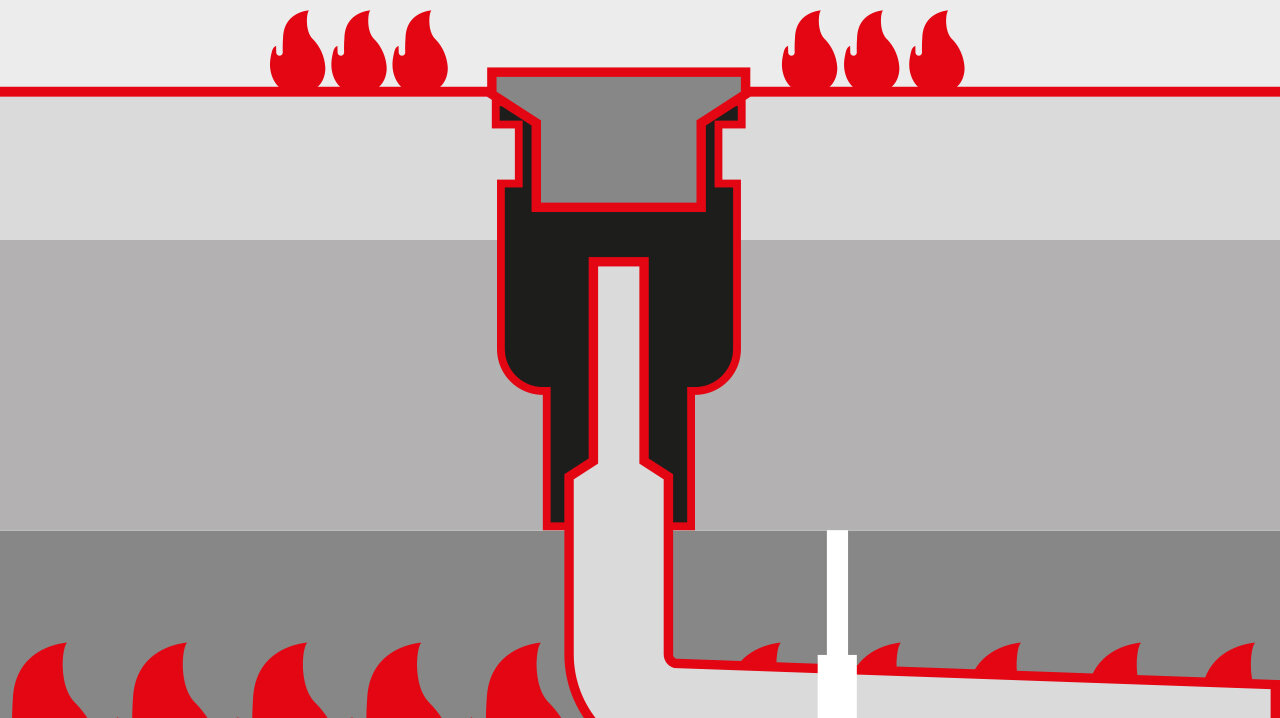

Fire-Kit & Quick-Fit:

Fire protection for KESSEL drains

With the Fire-Kit fire and smoke gas protection insert and the Quick-Fit pipe penetration seal, our range includes suitable accessories for the proper sealing of KESSEL drains against fire. The Fire-Kit ensures the fire-resistant sealing of the drain in the event of a fire, while the Quick-Fit pipe penetration seal represents a simple-to-install alternative to conventional filling materials for sealing core drill holes. The fire protection compound integrated into it seals any leaks between the drain body and the core drill holes in the event of a fire. Both the Fire-Kit and Quick-Fit fulfil the requirements of fire resistance class R120 for pipe penetrations.

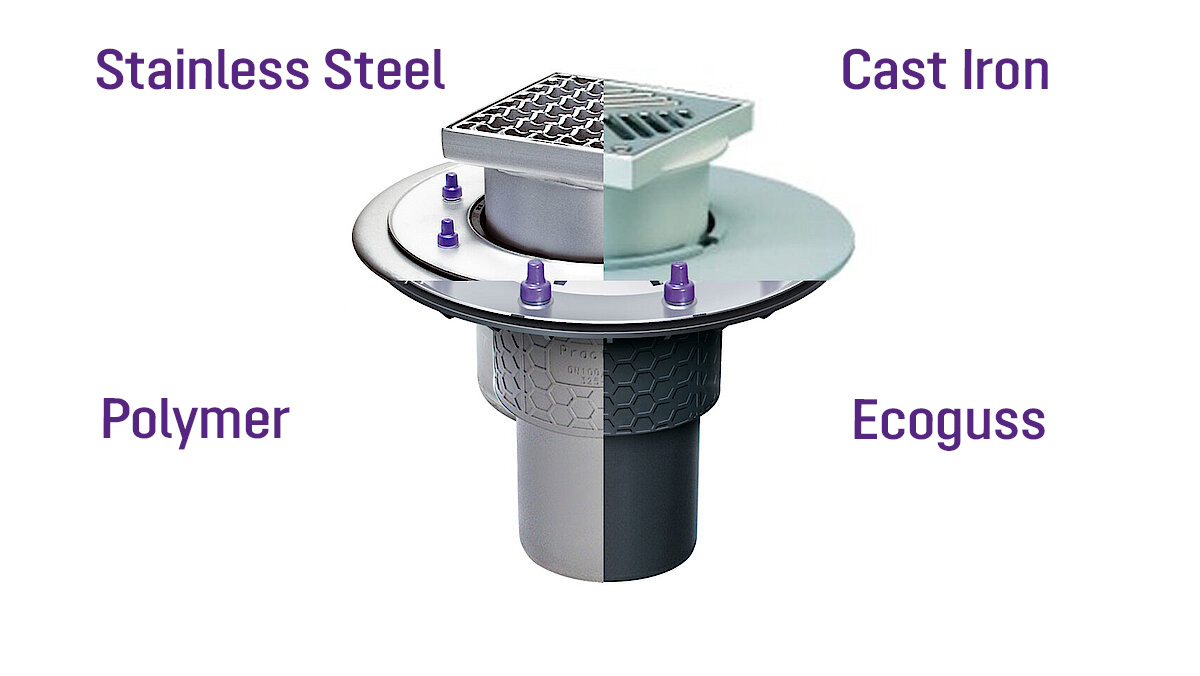

Individual combination of drains in a modular system

The right drains are not always available as a ready-made product for drainage systems with specific requirements. In such cases, modular solutions provide a remedy: You can use them to customise the right drains for your drainage task from a variety of compatible components and later adapt them to changed conditions without any problems.

Modular systems: regardless of the nominal size!

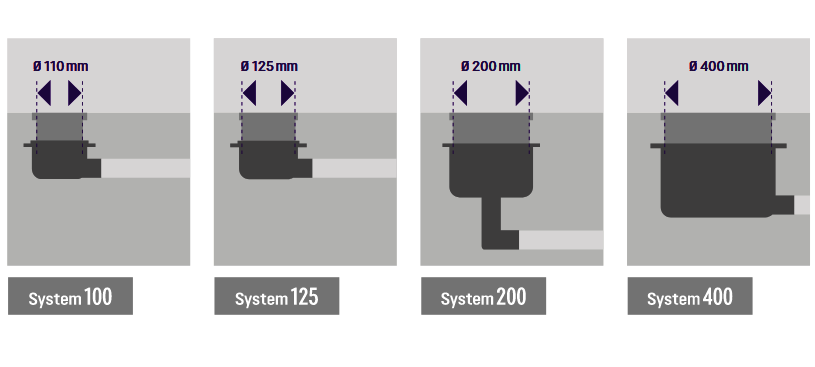

Modular systems are available for drains with different diameters. The diameter (push-fit connection between the upper section and drain body) is not dependent on the diameter of the connected drainage pipe – a drain with a specific diameter can therefore always be connected to pipes of all nominal sizes if the outlet connector is the appropriate size.

KESSEL modular systems

KESSEL offers modular drains with diameters ranging from 100 to 400 mm for bathroom, basement and project drainage as well as for outdoor use. The respective modular system can be customised from a range of drain bodies and materials and precisely tailored to the application and environmental conditions.